5 Key Factors to Consider When Renting a PortaPack Generator

In the world of refrigerated transport and storage, maintaining consistent power is non-negotiable. A single power outage can lead to spoiled goods, missed deliveries, and significant financial losses. Renting a PortaPack generator is an ideal solution to ensure your reefer (refrigerated) generators stay operational, even during emergencies or planned downtime. Designed for portability and reliability, PortaPack generators are perfect for the unique demands of the cold chain industry. Here are five critical factors to consider before renting one.

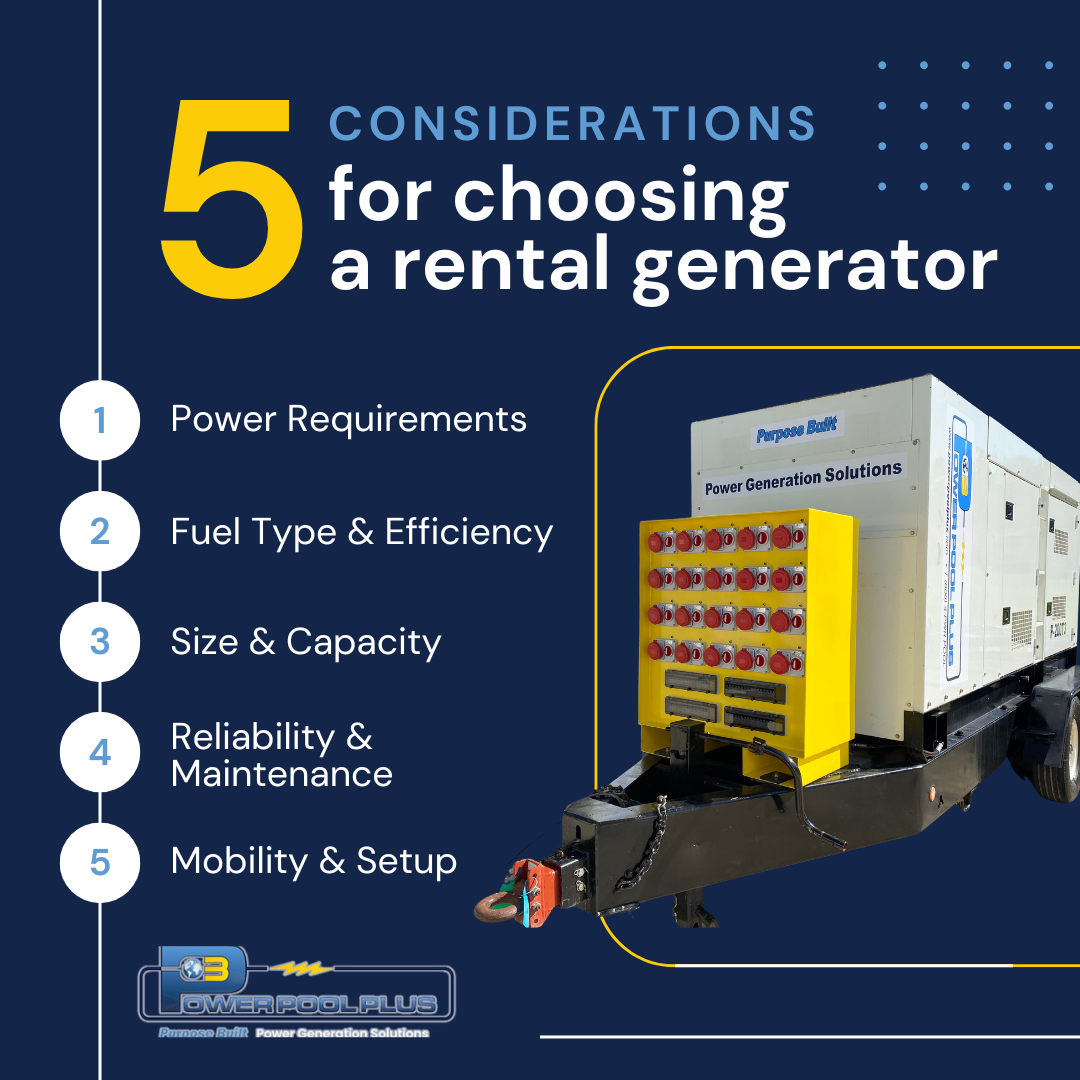

1. Power Requirements for Refrigerated Loads

Reefer generators have specific power demands to keep refrigerated containers, trucks, or storage units at optimal temperatures. When renting a PortaPack generator, calculate the total power required, factoring in the cooling units’ starting and running loads. PortaPack generators are designed to handle high-demand loads, ensuring your perishables remain at the right temperature without interruption. Be sure to communicate the specific wattage needs for your reefer units to ensure you rent a generator with the right capacity. If you're unsure of the wattage you need, we can help guide you.

2. Portability for On-the-Go Applications

Cold chain logistics often require mobility, especially for businesses transporting goods across regions or managing temporary storage sites. PortaPack generators are built for portability, making them easy to transport and set up at loading docks, warehouses, or on the road. Their compact design ensures they can be seamlessly integrated with reefer systems, providing reliable power wherever you need it. Whether you’re powering a single refrigerated container or multiple units, the PortaPack's mobility is a key advantage.

3. Fuel Efficiency for Cost-Effective Cooling

Fuel efficiency is a critical consideration for refrigerated operations, where generators often need to run continuously for extended periods. PortaPack generators typically run on diesel, offering a balance of cost-efficiency and reliability. With optimized fuel consumption, they ensure that your reefer units remain powered without driving up operational costs. Be sure to choose a generator with a fuel tank capacity and runtime that matches the duration of your transport or storage needs.

4. Reliability in Critical Situations

In the cold chain industry, downtime is not an option. PortaPack generators are designed for rugged use and consistent performance, ensuring that your refrigerated goods are never at risk of spoiling. When renting, confirm that the generator provider offers well-maintained equipment, technical support, and fast response times for troubleshooting. Look for rental agreements that include routine maintenance, replacement options, and 24/7 customer support to safeguard your operations.

5. Noise and Compliance

Noise can be a concern when operating generators near residential areas, urban warehouses, or at ports. PortaPack generators are equipped with sound attenuation features, ensuring quiet operation without compromising power output. Additionally, check that the generator meets emissions and safety standards, as compliance is often required for refrigerated transport in certain regions or facilities.

Final Thoughts

For businesses relying on refrigerated generators, renting a PortaPack generator is a smart, flexible solution to keep goods at the right temperature, no matter the circumstances. By assessing power requirements, taking advantage of PortaPack’s portability, prioritizing fuel efficiency, and ensuring reliability, you can protect your cold chain operations and avoid costly disruptions.

Don’t let power outages put your goods at risk. Rent a PortaPack generator today and keep your reefer units running smoothly!

Designing Sound Attenuation for Reefer Generators at Power Pool Plus

Reefer generators are essential for keeping perishable goods at optimal temperatures during transit, but the noise they produce can present challenges—from disturbing operators and the environment to failing noise regulations. At Power Pool Plus, we specialize in designing effective sound attenuation systems that balance performance with quiet operation, using advanced acoustics and smart engineering.

The Challenge of Reefer Generator Noise

Reefer generators generate noise from several sources—engine combustion, exhaust discharge, and the mechanical vibrations of moving parts. If not addressed, this noise can disrupt workers, disturb nearby areas, and create compliance issues with environmental and workplace regulations. Identifying the sources and frequencies of these sounds is the first step toward crafting effective sound control solutions.

Core Principles of Sound Attenuation

Our sound attenuation solutions focus on key methods to reduce noise transmission:

- Damping: This method involves using materials to reduce vibrations at the source, minimizing noise before it spreads.

- Isolation: By physically separating vibrating components from the generator frame, we limit noise transmission to the surrounding environment.

A Multi-Layered Approach to Noise Control

A Multi-Layered Approach to Noise Control

Building world-class sound attenuation solutions involves several key elements:

- Material Selection Matters

We choose high-performance materials like acoustic foam, fiberglass, and composite barriers. These materials offer superior sound absorption while being tough enough to withstand extreme temperatures, moisture, and the operational demands of reefer generators. The materials we use not only block noise but also ensure long-term durability.

- Custom Engineered Enclosures

Our custom-built enclosures are designed to trap and absorb noise while ensuring adequate ventilation to prevent overheating. These enclosures are lined with acoustic material to dampen noise, and their layouts are precisely engineered to fit the unique configuration of each generator.

- Vibration Control Solutions

Reducing vibrations at the source is critical to lowering noise levels. We integrate anti-vibration mounts, pads, and shock absorbers to reduce mechanical resonance and stop noise from radiating through the structure. This minimizes operational disruptions and ensures quiet performance.

Achieving the Perfect Balance: Quiet Power, Reliable Performance

At Power Pool Plus, we understand that reliable performance and quiet operation go hand-in-hand. Our sound attenuation enclosures help businesses meet noise regulations while maintaining efficiency. With precision-engineered enclosures, advanced materials, and vibration control solutions, we make sure reefer generators operate harmoniously, minimizing their noise footprint without sacrificing power.

Our goal? To deliver the quietest, most reliable reefer generators on the market—because powerful solutions shouldn’t have to be loud.

Prepare Your Reefer Containers for Hurricane Season with Power Pool Plus

As hurricane season approaches, ensuring that your reefer containers remain operational during storms is crucial for maintaining the integrity of your perishable cargo. At Power Pool Plus, we understand the importance of reliable power solutions for your refrigerated freight containers. Our Power Packs and PortaPacks are designed to keep your reefer containers powered and your goods safe, no matter the weather conditions.

A beautiful shot of lightning strike in the night sky over the city on a stormy night. Mystical cloudsA stunning view of a bustling cityscape at night, illuminated by the shimmering lights along the waterfront in AlkmaarHere are some essential tips to prepare your reefer containers for hurricane season:

1. Perform Regular Maintenance

Regular maintenance of your Power Packs and PortaPacks is key to ensuring they function optimally during a storm. Check for any signs of wear and tear, ensure fuel levels are adequate, and test the systems to make sure they are operating correctly. Preventive maintenance can help you avoid unexpected failures when you need power the most.

2. Secure Your Equipment

During a hurricane, high winds and flying debris can pose significant risks to your equipment. Secure your Power Packs and PortaPacks by anchoring them properly and protecting the cable ports with additional suitable covers. This will minimize the risk of damage and ensure that your power supply remains uninterrupted.

3. Have a Backup Plan

Despite the best preparations, sometimes things can still go wrong. Having a backup plan in place is essential. Consider having additional Power Packs or PortaPacks on standby, and ensure your team knows how to quickly navigate your freight yard and manage units if necessary. This redundancy can be a lifesaver during extended power outages.

4. Monitor Weather Conditions

Stay informed about upcoming weather conditions and be proactive in your preparations. If a hurricane is forecasted, ensure that all reefer containers are adequately powered and that your generators are in prime working condition. Early preparation can make all the difference in maintaining the integrity of your refrigerated goods.

5. Keep Emergency Contacts Handy

Have a list of emergency contacts readily available, including your generator service provider, local utility companies, and emergency services. Quick access to these contacts can expedite repairs and assistance in case of equipment failure during a storm.

6. Conduct Emergency Drills

Regularly conduct emergency drills with your team to ensure everyone knows their roles and responsibilities during a hurricane. Practicing these scenarios will help your team respond swiftly and efficiently, minimizing downtime and potential losses.

At Power Pool Plus, we are committed to providing robust and reliable power solutions for your reefer containers. Our Power Packs and PortaPacks are built to withstand harsh conditions and keep your operations running smoothly, even during a hurricane.

By following these tips and using our dependable power solutions, you can ensure that your reefer containers remain operational and your perishable goods stay protected throughout hurricane season.

Stay prepared and stay powered with Power Pool Plus.

For more information and expert advice, visit our website or contact our team today.

Global Food Waste Prevention: Innovations and Insights

Addressing the Food Waste Crisis

Food waste is a pressing global issue, with about a third of the food produced annually going to waste, according to the United Nations’ Food and Agriculture Organization. A recent study from the University of Michigan reveals that nearly half of this waste, approximately 620 million metric tons, could be eliminated by implementing fully refrigerated food supply chains worldwide.

Aaron Friedman-Heiman, a master’s student at the University of Michigan’s School for Environment and Sustainability and Ross School of Business, spearheaded this study. He highlights the enormous potential for reducing food loss and waste through supply-chain optimization. The study estimates that inadequate cold-chain infrastructure is a major contributor to global food loss, leading to significant greenhouse gas emissions.

Environmental Impact: Poor cold-chain infrastructure results in the emission of 1.8 billion tons of carbon dioxide equivalents, accounting for 28% of annual greenhouse gas emissions in the U.S. Therefore, improving warehousing and other aspects of the cold chain is crucial for minimizing food waste and mitigating its environmental impact.

The Importance of Cold-Chain Logistics in Food Preservation

Cold-chain logistics is vital in the food industry. It involves the transportation of temperature-sensitive goods in a temperature-controlled environment. This process ensures the freshness and safety of perishable goods, extending their shelf-life, and reducing the risk of spoilage and waste.

Global Food Waste: A Challenge and Opportunity

Global food waste has significant environmental, economic, and social implications. Yet, it also presents an opportunity. By improving cold-chain logistics, we can reduce food waste and its impacts, including:

- Increased greenhouse gas emissions

- Economic losses for producers and consumers

- Wasted resources used in food production

- Increased pressure on land and water resources

- Threats to food security and sustainable development

Advancements in Cold-Chain Technology

Cold-chain logistics technology has seen significant advancements in recent years. These improvements have the potential to revolutionize the way we handle perishable goods. From IoT devices to AI-powered analytics, these technologies are making cold-chain operations more efficient and reliable. They help maintain the quality of food products, reducing waste, and promoting sustainable living.

Refrigerated Transport and Its Impact

Refrigerated transport plays a crucial role in the cold-chain. It ensures that perishable goods are kept at the right temperature during transit, preserving their quality and safety. With advancements in refrigeration technology, transport vehicles can now maintain more consistent temperatures. This reduces the risk of spoilage and contributes to global food waste prevention.

The Role of Reefer Generators in Cold-Chain Efficiency

Refrigerated generators (aka reefers) are another key component of the cold-chain. They provide the power needed to keep refrigeration units running during transport. By improving the efficiency of these generators, we can reduce energy consumption and environmental impact. This also leads to cost savings, making cold-chain operations more sustainable and economically viable.

Resource Management for Sustainable Cold-Chain Operations

Effective resource management is key to sustainable cold-chain operations. It involves optimizing the use of energy, equipment, and manpower to reduce waste and improve efficiency. By adopting best practices in resource management, businesses can reduce their environmental footprint and achieve significant cost savings, making their operations more sustainable and profitable.

Implementing IoT and AI for Smarter Logistics

The use of IoT and AI in cold-chain logistics is a game-changer. These technologies enable real-time monitoring and predictive analytics, enhancing the efficiency and reliability of operations. With IoT devices, businesses can track the condition of their goods in real-time. AI, on the other hand, can analyze this data to predict potential issues and suggest preventive measures.

Real-Time Data Tracking and Its Benefits

Real-time data tracking provides businesses with up-to-the-minute information about their operations, enabling them to make informed decisions. By tracking data in real-time, businesses can quickly identify and address issues. This reduces the risk of spoilage and waste, contributing to global food waste prevention and sustainable living.

Overcoming Cold-Chain Logistics Challenges

Despite advancements in cold-chain logistics technology, several challenges remain. These include maintaining temperature control, ensuring energy efficiency, and addressing the last-mile delivery problem. However, with continuous innovation and collaboration among stakeholders, these challenges can be overcome, paving the way for more efficient and sustainable cold-chain operations.

Addressing the Last-Mile Delivery Problem

The last-mile delivery problem involves maintaining the quality and safety of perishable goods during their final journey to the consumer. Innovative solutions, such as mobile cold storage and smart containers, are being developed to address this issue. These technologies help ensure that perishable goods reach consumers in optimal condition, reducing food waste and promoting sustainable living.

Case Studies: Success Stories in Cold-Chain Logistics

Several companies have successfully implemented advanced cold-chain logistics technology to reduce food waste. For instance, some have leveraged IoT and AI to enhance their operations, resulting in improved efficiency and reduced spoilage. Others have used refrigerated transport generators to maintain optimal temperatures during transport. These success stories serve as a testament to the potential of cold-chain logistics technology in addressing global food waste.

The Future of Cold-Chain Logistics Technology

The future of cold-chain logistics technology looks promising. With continuous innovation and advancements in technology, the sector is poised to become more efficient and sustainable. The integration of IoT, AI, and blockchain technology is expected to revolutionize the industry, offering real-time tracking, predictive analytics, and enhanced traceability.

Moreover, the use of sensor technology and smart containers could further improve the quality and safety of perishable goods. These advancements will not only reduce food waste but also contribute to cost savings and improved food security.

Conclusion: The Role of Stakeholders in Reducing Food Waste

The fight against global food waste is a collective effort. Stakeholders across the supply chain, from farmers to retailers, have a crucial role to play. By adopting advanced cold-chain logistics technology and sustainable practices, they can significantly reduce food waste and contribute to a more sustainable future.

Moreover, consumers, policymakers, and technology providers also have a part to play. Through education, regulation, and continuous innovation, we can make a significant impact on global food waste prevention.al food waste prevention.

Custom Generator Solutions for Refrigerated Cargo

As the demand for transporting temperature-sensitive goods continues to rise, the importance of reliable refrigerated transport (reefer) solutions has never been more critical. From pharmaceuticals to perishable food items, ensuring these goods reach their destination in pristine condition is a top priority for shipping companies. Custom built power generation solutions for refrigerated transport are key to meeting these stringent requirements. Here’s a look at how custom reefer genset solutions are powering the cold chain logistics industry.

Understanding Reefer Gensets

Reefer gensets, or refrigerated generators, are specialized power generation units designed to maintain the necessary temperature controls within refrigerated containers during transport. These units are essential for the movement of refrigerated cargo, particularly when transported via trucks, trains, or ships where access to a stable power source is not always guaranteed.

Why Custom Solutions?

Every refrigerated transport operation has its unique set of challenges. Factors such as the type of goods being transported, the duration of the shipment, and the specific temperature requirements all necessitate tailored power solutions. Custom power generation solutions for refrigerated transport are designed to meet the precise needs of each shipment, ensuring optimal performance and reliability.

Custom Reefer Genset Solutions

Custom reefer genset solutions take into account the cargo's size, weight, temperature sensitivity, and the journey's length to ensure that the goods remain at the right temperature throughout transit. By customizing the power generation units, companies can avoid the one-size-fits-all approach, which may not be suitable for all types of refrigerated cargo.

Benefits of Customization

The benefits of opting for custom reefer genset solutions include increased efficiency, reduced operational costs, and enhanced protection for sensitive goods. Customization can lead to gensets that are more fuel-efficient, have better temperature control, and are designed to fit perfectly with the transport containers in use. This tailored approach can also extend the lifespan of the gensets, as they are built to withstand the specific conditions they will face.

Innovation in Refrigerated Cargo Power

The refrigerated cargo shipping industry continues to innovate, with new technologies improving the efficiency and sustainability of reefer gensets. Companies now offer gensets with smart monitoring systems that allow for real-time tracking and adjustments to temperature settings. These advancements ensure that custom reefer genset solutions are not only reliable but also at the forefront of technology.

Partnering with Experts

When it comes to acquiring custom reefer genset solutions, partnering with an experienced manufacturer like Power Pool Plus is crucial. Our team of experts can assess your specific requirements and design a power generation solution that aligns with your operational needs. With the right partnership, you can secure the robust and reliable reefer generators necessary for successful refrigerated cargo shipping.

Custom built power generation solutions are integral to the success of refrigerated transport. With the right genset in place, companies can ensure that their temperature-sensitive goods are transported safely and efficiently, maintaining quality and freshness upon arrival. As the industry evolves, Power Pool Plus's custom solutions will continue to play a pivotal role in the advancement of refrigerated cargo power.

Power Pool Plus, Inc. expands manufacturing with new operation in South Carolina

We are very excited to announce our plans to establish a new manufacturing center in Greenwood, South Carolina.

A multi-million dollar investment, projected to create 21 new jobs, will enable our company to service the increased demand for our manufactured generator products and expand our contract metal fabrication operations.

This new 30,000 sq ft building located on 12 acres provides the space needed to effectively increase our production capability, yet ensure sufficient capacity for future expansion.

The present location in Alpha, New Jersey, will remain fully staffed as the Northeast Rental and Service Center and continue with its primary focus on serving all northeast reefer cargo operators from northern Virginia to Maine with exceptional service and support.

All current manufacturing orders will be completed in our New Jersey facility. All new orders are scheduled to begin production in South Carolina early in the fourth quarter of 2020.

Over the past 30 years, Power Pool Plus has adapted to change. This latest move reflects a recognition that refrigerated cargo transportation is growing, and the demand for reliable purpose-built power generation equipment has never been higher.

Please look for more details and information in the coming weeks/months.

Ted Shelson

VP Marketing

Power Pool Plus

It's all about the cold chain

The need for perishable goods has never been greater. Keeping the cold-chain intact is critical not only to end-users of our reefer generators but to our entire community at large.

Like most companies, Power Pool Plus is doing our best to keep our team safe and healthy amid #COVID19 concerns by maintaining social distancing whenever possible, limiting access into our facility, and allowing those who can work from home to do so.

Please note that our operation remains open and continues to work hard filling orders for both new and re-manufactured Power Packs. Our service team is on-call and ready to serve.

We would like to extend a special thank you to our customers, many of whom are the port operators working on the front lines in areas hardest hit by the corona-virus outbreak.

And thank you to our many vendors that continue to operate and supply us with the raw materials needed to produce quality Power Packs that reefer operators have come to expect from Power Pool Plus.

Having quality fresh food on our shelves will help make the challenges of getting through this crisis just a little more bearable. Together we can all do our part to keep fresh produce moving.

We are here when you need us.

Power Packs, Mobile PortaPacks™, Service, Rentals

Considering a used Power Pack? Here's how to reduce risk.

Used reefer gensets, known as power packs, can offer refrigerated container operators both large and small an inexpensive way to expand their operation and increase refrigerated container throughput. Lower initial investment costs of used power packs also reduces financial barriers, allowing start-up operations the flexibility to gain entry into the reefer market.

Yet, buying anything used is risky. Knowing what to look for is key.

Understand your needs first.

Since the supply of preowned power packs may be limited, there’s a tendency to purchase the first one that comes along, usually the one that first appears to be in good condition. But it’s very important that the power pack you choose fits your needs correctly. A generator that is too large – having a kW rating that’s higher than your expected load - can be almost as bad as having one that’s too small for your needs. Our article on wet-stacking highlights this.

If your operation will need to power 20, 30, or 40+ reefer containers, then be sure your power pack is sized to meet at least 70% of that number consistently. In this way, you will not risk unexpected generator shut-down due to overloading and your connected load will be sufficient enough to avoid problems associated with wet-stacking.

Be realistic

Good or bad, used power packs will have a history to them. It's fair to assume that before being replaced most power packs are typically used right up to the point of near failure; until the very last bit of productivity is squeezed from their essence.

What remains is a worn-out engine that’s unable to maintain horsepower, a generator with windings that are nearly torn from the stator and unable to produce electrical current safely, a rotten container that’s rusted through, broken and unusable receptacles, plus many other failings. With thousands of dollars in perishable cargo at stake, used machines are hardly something that can be purchased AS-IS and be expected to provide quality power generation. This is the risk.

Even if the used power pack that you are considering is not nearly as bad as the one pointed out in this example, it is safe to say that purchasing a used machine will offer limited life expectancy and require some sort of additional investment. Major failures can happen at any time creating huge and unexpected repair bills with potentially long power pack downtime – what’s that worth?

These costs are real and need to be figured into the overall operating expenses of purchasing and owning a used power pack with questionable history and limited records availability.

A better solution,

One that won’t leave you stranded like an old, worn-out power pack might.

Allow Power Pool Plus to provide the right used power pack for you. Our experienced team will identify the right generator package that’s properly sized to meet your requirements. Because finding one that’s sized correctly for your needs may not always be easy.

Through our comprehensive inspection process and in-depth operational evaluations, Power Pool Plus offers peace-of-mind on every used generator package purchased through us.

Here’s how we do it

Once a used generator passes our initial operational analysis, it goes through a process that we call re-qualification.

The engine and generator are the core components of any refrigerated container power pack. So our re-qualification process focuses on documented and historical failure facts based on each make and model genset. And with 30 years’ experience there is quite a bit of history to lean on.

Our intent is to extend the service life of a known low hour engine or generator set at a cost savings to our customers – often times as much as half the cost of purchasing new.

Understanding that the negative effects of fuels, oils, coolants, water, UV rays, age, and dry rot are the #1 enemies of power units, we go through an exhaustive process on any used machine that we evaluate. Key engine and generator parts are evaluated and replaced as necessary to ensure a product that is capable of handling the demands of typical power pack operations.

Other components like the shipping container enclosure, fuel tank, receptacle panels, and controls are reconditioned or replaced as needed.

The end result will allow your operation to be successful through owning a used reefer power pack with the assurances of professional inspection and re-qualification provided at a significantly reduced cost over a new machine.

While it’s difficult to eliminate all risk when purchasing used gear, our team reduces the chances of failure significantly and provides our customers with equipment that will offer productive output while maximizing your operation’s profitability for years to come. And isn’t that why you’re looking for a power pack in the first place?

Don’t take the risk on your own. Trust Power Pool Plus to deliver results and savings.

*Remember to properly maintain your equipment according to manufacturer’s recommendations to ensure long operational life with minimal downtime.

Power Pool Plus welcomes LATAM sales manager

Power Pool Plus Welcomes Jose Alberto Castillo Magaña as Sales Manager of LATAM

Alberto provides his experiences in customer support to port equipment sales

(Alpha, New Jersey USA) Power Pool Plus is proud to announce the addition of Alberto Castillo as our Regional Sales Manager of Latin America. Alberto joins Power Pool Plus with past experience in addressing the heavy lifting requirements of both port and construction equipment operators. Mr. Castillo will be responsible for developing new business relationships and promoting our reefer generator products and related services throughout Mexico, Central America, and South America. Mr. Castillo is trained in mechanical engineering and is an accomplished sales professional with experience in solving unique challenges that maximize customer efficiencies.

Ports throughout Latin America are ever expanding their footprint in the perishable goods trade. This new role with Power Pool Plus will be to provide unique power generation solutions for port operators that are actively engaged in the throughput of refrigerated container cargo. Alberto is no stranger to the requirements of port operations. Based out of Mexico City, Mr. Castillo has most recently represented Taylor Machine Works International as the Regional Sales Manager of Mexico and SITSA in Mexico City as Sales Representative for Kalmar equipment and terminal tractors. Both roles addressed the capital equipment needs of port facilities.

According to Adam Hulse, VP Sales, “Having a regional representative in Latin America has been a goal for Power Pool Plus for some time. Alberto’s valued experiences and innate appreciation for meeting customer expectations is a perfect fit to the character of Power Pool Plus that we believe our customers in this region will benefit from. Everyone on our team is very excited to have him on board with us.”

“Power Pool Plus has the right products to address port operators throughout Latin America,” says Mr. Castillo. “I am excited about this opportunity to apply my knowledge and creative imagination in helping our customers with their reefer power needs.”

From spikes in seasonal cargo throughput to the efficient use of power packs to mitigate challenges in dependable ground power, Power Pool Plus is committed to helping port operators throughout Latin America to be successful in managing the ever expanding volumes of refrigerated container cargo. Mr. Castillo’s experiences and professional acumen will be an asset not only to Power Pool Plus, but to the customers that he will effectively serve.

4 Conversation Starters to Creating a Custom Power Pack

A power pack that fits exactly into your unique work environment can help maximize workflow efficiencies and help your team save both time and money.

What if you had a customized power pack that was designed around your operation and the challenges which you face daily?

Typical designs can feature 30, 40, or 50 or more receptacles all placed in one location on the power pack enclosure. Yet, unique yard layouts, stacking limitations due to container handling equipment, and other defining factors create challenges in trying to position all your reefer  stacks around a single power source. These challenges disrupt operations creating extra labor time.

stacks around a single power source. These challenges disrupt operations creating extra labor time.

But it doesn’t have to be this way.

And it all begins with having a complete understanding of what the operator is looking to accomplish.

4 questions that help get the conversation started might be.

1) How many plugs (or reefer cord connections) will be needed?

- Power packs that operate with too many unused plugs on a regular basis operate inefficiently and can create engine problems due to wet-stacking.

- Having the right amount of receptacles that maintain a level of capacity near 75% is ideal for engine health and fuel efficiency.

2) Where will the reefer stacks be positioned in relation to the intended power pack placement?

- Too tight and critical airflow might be affected. Creative thought on power pack design can address this.

- Too far away and reaching the power pack may be challenging. Bringing the receptacles to the reefer stacks through the use of remote trees may be needed.

3) What is the expected run-time between fuel deliveries?

- Sizing the fuel tank appropriately to this key factor can be the difference that allows an operator to run non-stop between deliveries.

4) What is the operating climate?

- Certain elements of design can help mitigate the negative effects of either tropical heat and humidity or artic cold.

Allow Power Pool Plus to create a custom power pack solution for you. Contact us today.

Recent Custom Projects