A Perfect Storm flooding reefer terminals (and it's not water)

With the ever-increasing demand for year-round fresh fruits and vegetables, refrigerated containers full of perishable produce are hitting US ports at staggering rates. The need for ports to accept these reefers is demanding. But will this flood of reefers swamp terminal operators?

Why are refrigerated containers stuck in port?

In some cases, container ships arrive into port with more reefer to off-load than initially forecast, putting an incredible strain on the port operator to round up enough reefer receptacles for a load of containers.

Under normal times this may not be a problem. But these are not normal times.

Increased refrigerated container traffic combined with multiple ships arriving back-to-back allows little time for some port operators to move reefer off the terminal before the next ship arrives. Compounding these challenges is the decreased availability of truckers due to COVID. Without truckers to haul this cargo, everything sits - preventing terminal operators from moving reefer out of the port quickly.

But unlike dry containers that can be stacked and positioned just about anywhere in the yard, refrigerated containers require a constant supply of electricity to keep the perishable goods within temperature specs. Every reefer unloaded onto the terminal needs to quickly find an available electrical connection. The financial risk of cargo spoilage is real and is a challenging responsibility for port operators.

Here's a solution.

Ideally, moving these perishable loads out of the port as quickly as possible is the best solution. But when that's not an option, diesel-powered generators, called Power Packs, offer port operators the flexibility to ramp up reefer capacity quickly to handle sudden increases in container throughput. Power Packs uniquely accommodate thirty to fifty or more reefer cord connections. And because they are diesel-powered, they can be positioned anywhere space is available.

- Through short term rentals, terminal operators can quickly add capacity during traditional spikes in reefer throughput.

- Longer rental terms can help operators mitigate the disruptions from lengthy port construction projects.

- Custom designed power packs configured to meet an operators' unique requirements can be purchased for a permanent reefer power solution.

To weather the flood of reefer hitting your dock, Power Pool Plus maintains a fleet of power packs and their highly versatile cousin, PortaPacksTM, to help manage and keep the refrigerated containers safe while under the terminal operator's care.

How many reefer plugs do you need?

Ted Shelson

VP Marketing

Power Pool Plus

4 Essential Troubleshooting Tips for Power Packs

Reefer operators have only one thing on their mind, make sure that the refrigerated cargo under their care is kept safely to spec.

Having a diesel genset go down is never an option. But understanding a few of the issues that may cause a diesel generator to fail, may help to save the refrigerated loads and avoid a service call in the middle of the night.

Thankfully, most power pack failures are quickly resolved, and with some basic knowledge, can be managed successfully without having to wait for service.

To help your team through some of the most common issues, here are a few troubleshooting tips.

Power Pack will not start

- Check that the battery disconnect switch is closed, and the batteries are charged.

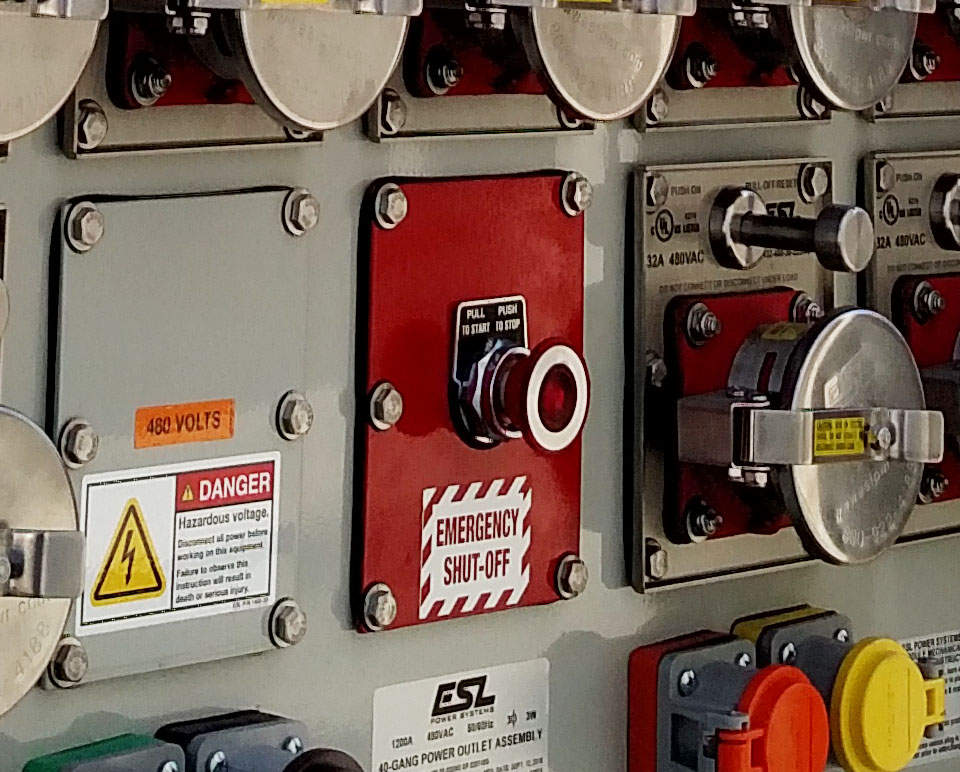

- Are the Emergency Stop Buttons

engaged (pushed in)? Pulling them out may start the generator. Ensure that no one is working on the generator or is inside the container enclosure before pulling out any emergency stop button. There are two E-Stop buttons - one located outside the main door and another inside near the control panel.

engaged (pushed in)? Pulling them out may start the generator. Ensure that no one is working on the generator or is inside the container enclosure before pulling out any emergency stop button. There are two E-Stop buttons - one located outside the main door and another inside near the control panel. - Is there fuel in the tank?

Yes, it may seem obvious, but our road service team has been called out many times only to discover a power pack that was allowed to run out of fuel. Note: after refueling, prime all fuel filters with fuel before restarting the engine. This will ensure a quick start and protect the fuel pump from damage.

Yes, it may seem obvious, but our road service team has been called out many times only to discover a power pack that was allowed to run out of fuel. Note: after refueling, prime all fuel filters with fuel before restarting the engine. This will ensure a quick start and protect the fuel pump from damage.

Power Pack shuts down without warning

- Fuel issues are the leading cause of power pack failures in ports. Poor fuel quality means clogged fuel filters. Change fuel

canisters and elements, and drain and clean fuel/water separators frequently. Prime all fuel filters.

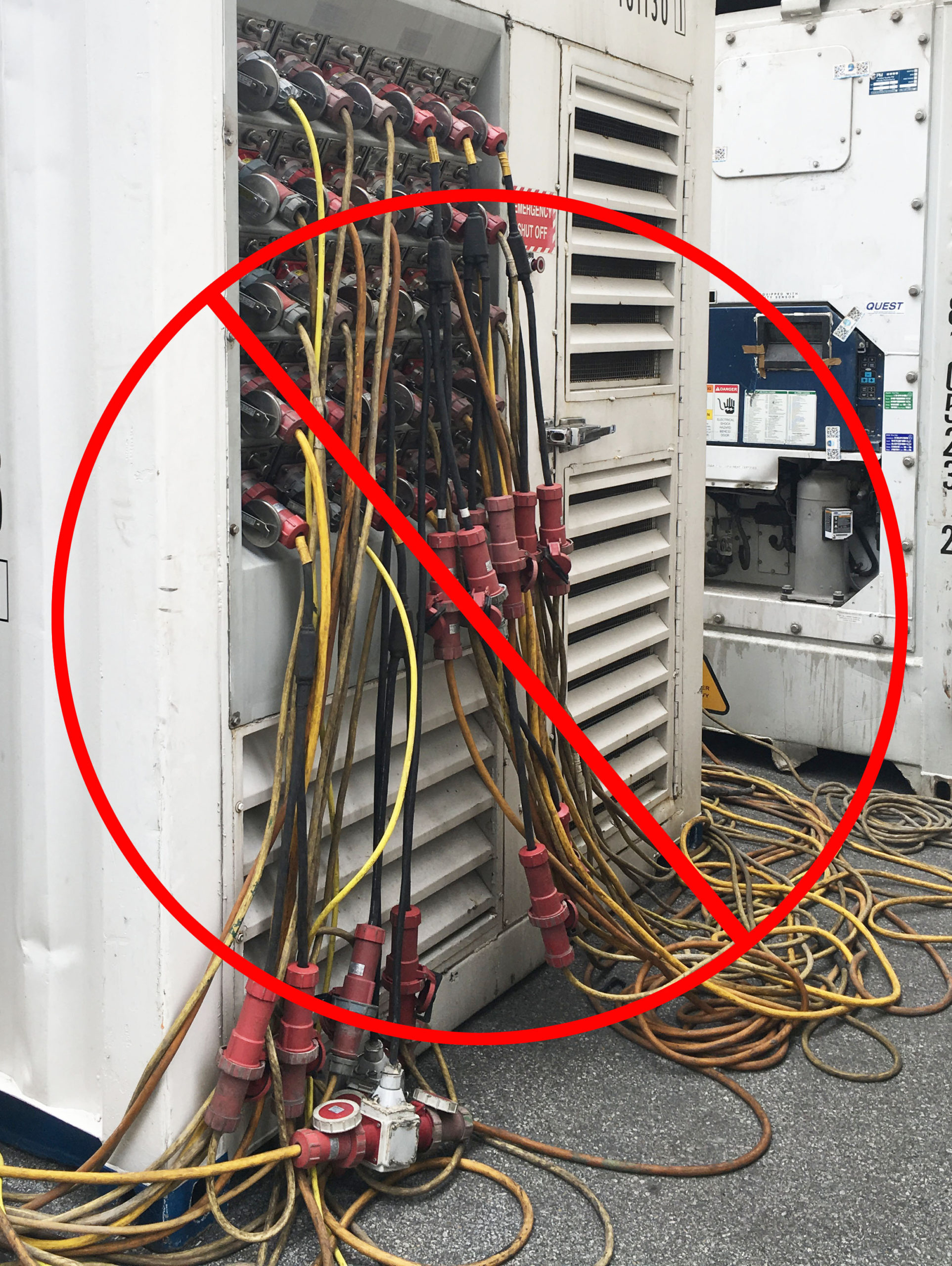

canisters and elements, and drain and clean fuel/water separators frequently. Prime all fuel filters. - Overloading power packs is a common problem, and can easily lead to generator shut down and loss of the connected load. It happens when the

reefer operator has more refrigerated containers to keep powered than available receptacles on the power pack. Beware of commonly used splitters to add capacity to power pack receptacle panels. An over-zealous operator may be inclined to connect as many as double the rated capacity of the power pack. It won’t take long to exceed the limitations of the power pack causing the main breaker to trip and cutting electrical current from the generator to the plugs.

reefer operator has more refrigerated containers to keep powered than available receptacles on the power pack. Beware of commonly used splitters to add capacity to power pack receptacle panels. An over-zealous operator may be inclined to connect as many as double the rated capacity of the power pack. It won’t take long to exceed the limitations of the power pack causing the main breaker to trip and cutting electrical current from the generator to the plugs. - Low oil level, low coolant level, and other alarm faults can cause your power pack to shut down to protect itself from damage. Before each startup, or at regular intervals during 24hr run cycles, visually inspect for leaks and worn parts, check and top off all fluids to proper levels, adjust loose belts or replace as necessary, and remove debris from the container compartment.

Power Pack runs but does not produce electrical power

- Check that the main breaker is engaged. Every power pack is different, but commonly located near the main control panel. Best practice is to engage the main breaker AFTER starting the engine.

Power Pack produces black exhaust smoke when running

- Black exhaust smoke is a common sign of wet-stacking caused by under-loading a generator. Power Packs come in many sizes,

typically identified by plug count (20-plug, 30-plug, 40-plug, and so on). They can carry a load equal to that number of refrigerated containers. Connecting less than half that amount over long periods is equivalent to starting your car and letting it run idle all day long, which is not ideal for the vehicle. A diesel engine will create soot, or unburnt fuel when operated like this. Too much of this carbon buildup will rob the diesel engine of vital power. Loading up the power pack to its capacity should clear most black smoke issues. If not, a load bank may be needed to replicate or add additional load to the power pack. Power Pool Plus can assist in this.

typically identified by plug count (20-plug, 30-plug, 40-plug, and so on). They can carry a load equal to that number of refrigerated containers. Connecting less than half that amount over long periods is equivalent to starting your car and letting it run idle all day long, which is not ideal for the vehicle. A diesel engine will create soot, or unburnt fuel when operated like this. Too much of this carbon buildup will rob the diesel engine of vital power. Loading up the power pack to its capacity should clear most black smoke issues. If not, a load bank may be needed to replicate or add additional load to the power pack. Power Pool Plus can assist in this.

Final Thought:

Power Packs are essential equipment for nearly every reefer operator. Setting aside even a small amount of time to understand a few of these concerns and how to address them quickly will go a long way in protecting your power pack and the valuable refrigerated load connected to it.

Questions? Contact Us.

The Power Pool Plus Service Team is available anytime to help keep your power pack reefer gensets running at their best, day or night.

Ted Shelson

VP Marketing

Power Pool Plus

5 Solid Cases for Renting Your Next Power Pack

Renting Power Packs for your reefer operation not only makes financial sense but when compared to renting other power generation solutions, Power Packs remain the best choice.

And because so much is a stake with every refrigerated container under your care, here are five reasons why your rental choice should be a Power Pack and not just any standby generator.

- Operational vs. Capital Expense – Renting power packs allows a more flexible approach to managing finances. Rather than budgeting a considerable expense all at once, rentals can provide a more economical method for handling day to day operations.

- Seasonal spikes in reefer throughput – Short term increases in refrigerated container throughput can create challenges for even the most prepared reefer operator. Power packs afford peace-of-mind during peak seasons, making large ship calls, day or night, more manageable.

- Port construction projects – When your reefer yards get disrupted during port construction projects, rental power packs assist port operators by creating temporary diesel-powered reefer yards in areas of the port where electrical infrastructure may not exist.

- More than a standby generator – Compared to rolling up a standard generator set from your local rental company, consider the unique design that power packs offer. Built with the reefer operator in mind, power packs feature integrated receptacles mounted on the enclosure, ease of service, and a footprint that fits neatly into the world of container handling. Renting a power pack is the more logical choice for reefer operators.

- Most importantly, Flexibility – Instant reefer yard - anyplace, at any time. Without the restriction of fixed electrical outlets, the reefer operator with diesel power packs at his disposal can set up a reefer yard anywhere space allows, big or small, in a short time. Renting power packs allows any port to enter the world of reefer cargo quickly.

Power Pool Plus offers the right rental equipment that's backed by a committed team of service specialists. We understand the critical nature that power pack generators play in the business of handling refrigerated containers.

Learn about our Power Pack rental products

Ted Shelson

VP Marketing

Power Pool Plus

Power Pool Plus, Inc. expands manufacturing with new operation in South Carolina

We are very excited to announce our plans to establish a new manufacturing center in Greenwood, South Carolina.

A multi-million dollar investment, projected to create 21 new jobs, will enable our company to service the increased demand for our manufactured generator products and expand our contract metal fabrication operations.

This new 30,000 sq ft building located on 12 acres provides the space needed to effectively increase our production capability, yet ensure sufficient capacity for future expansion.

The present location in Alpha, New Jersey, will remain fully staffed as the Northeast Rental and Service Center and continue with its primary focus on serving all northeast reefer cargo operators from northern Virginia to Maine with exceptional service and support.

All current manufacturing orders will be completed in our New Jersey facility. All new orders are scheduled to begin production in South Carolina early in the fourth quarter of 2020.

Over the past 30 years, Power Pool Plus has adapted to change. This latest move reflects a recognition that refrigerated cargo transportation is growing, and the demand for reliable purpose-built power generation equipment has never been higher.

Please look for more details and information in the coming weeks/months.

Ted Shelson

VP Marketing

Power Pool Plus

Is your fuel killing your power pack? How to mitigate fuel quality issues.

Bad fuel kills power packs. Don't allow poor fuel quality to affect power pack performance.

Poor fuel quality is the number one cause for power pack failure and engine shutdown. Contaminated fuel in storage tanks can create particulate that becomes suspended in the fuel during power pack transportation, movement, or refueling. This particulate restricts fuel flow by clogging fuel filtration systems.

Fuel related issues can be more than an inconvenience. Clogged filters can damage expensive fuel pumps and injectors, not to mention the downtime associated with these repairs.

How does fuel contamination happen?

Many outside elements can affect fuel quality, either by the introduction of debris or through the degradation of the fuel itself. Here are some common challenges that power  pack operators face:

pack operators face:

Water

- Reefer yards located near open water, face an unavoidable challenge. Temperature changes create condensation, humidity enters through ventilation ports, and the refueling process allows for the introduction of water.

- Water promotes bacterial growth creating one of the more common contaminants; micro-organisms, called diesel bugs, live and die in the fuel forming debris.

- Rust particulate and corrosion on critical engine fuel system components are a result of water in fuel tanks.

Hard Particles

- Windblown sand and dust are common problems in many reefer yards. Often these contaminants enter the fuel tank during refueling.

Soft contaminant particles

- Overheated and degraded diesel fuel enters the tank through the return line. These particles act like gum and coat filters with a black asphaltene-like substance, leading to power loss and engine shutdown.

These are just a few ways that fuel contamination occurs. Understanding these challenges and taking preventative action where possible are the first lines of defense.

Here's what we're doing about it.

We equip all Power Pool Plus rental power packs with a primary fuel filtration system as the first step in removing contaminants.

During routine power pack inspections, take note of the filtration system located upstream from the standard fuel filters. Empty the water collection bowl and replace the filtration element as needed.

Doing this simple process will:

- Prevent costly injector damage.

- Increase the operational life of downstream filters

- Save time and money by eliminating unplanned maintenance and unscheduled downtime from fuel system component failure.

A best practice is to keep several extra fuel filters and cartridges on-hand and replace them at the first signs that the engine is starving for fuel.

Ensuring the quality of the fuel is the responsibility of the power pack operator. Don't allow poor fuel quality to affect the performance of your power pack; the critical load of reefer containers under your care is counting on it.

Ted Shelson

VP Marketing

Power Pool Plus

It's all about the cold chain

The need for perishable goods has never been greater. Keeping the cold-chain intact is critical not only to end-users of our reefer generators but to our entire community at large.

Like most companies, Power Pool Plus is doing our best to keep our team safe and healthy amid #COVID19 concerns by maintaining social distancing whenever possible, limiting access into our facility, and allowing those who can work from home to do so.

Please note that our operation remains open and continues to work hard filling orders for both new and re-manufactured Power Packs. Our service team is on-call and ready to serve.

We would like to extend a special thank you to our customers, many of whom are the port operators working on the front lines in areas hardest hit by the corona-virus outbreak.

And thank you to our many vendors that continue to operate and supply us with the raw materials needed to produce quality Power Packs that reefer operators have come to expect from Power Pool Plus.

Having quality fresh food on our shelves will help make the challenges of getting through this crisis just a little more bearable. Together we can all do our part to keep fresh produce moving.

We are here when you need us.

Power Packs, Mobile PortaPacks™, Service, Rentals

5 Ways to Protect Your Power Pack During Emergencies

COVID-19 related events are having a profound effect on local grocery store inventory. The resilience of the supply chain will have a significant impact on the health and welfare of all of us.

Even those that until now may not have fully understood the role that we in the refrigerated transportation industry play in keeping fresh produce on the shelves, they are indeed watching us now.

One key element is the Power Pack reefer generator to ensuring the successful throughput of the perishable cargo under your care.

All of us here at Power Pool Plus remain available to assist where possible. Your team, however, is the first line of defense against unexpected generator shutdowns. And the proper maintenance practices that you follow may make the difference between success and failure.

Here are some fundamental steps that everyone on your team should know in regards to Power Pack maintenance.

- Keep extra fuel filters on hand - Bad fuel is the #1 cause for generator failure. Checking for clogged fuel filters is an excellent first action to power pack shut down. Replace each as needed and be sure to correctly prime each filter before installation. If equipped with a RACOR filtration system, visually check for debris and clean as necessary.

- Avoid low reefer count per Power Pack - In other words, try to limit the times that each power pack is under-loaded, or under 50% capacity. Under-loaded Power Packs will cause a condition known as wet-stacking, indicated by thick black exhaust smoke, which may limit engine performance when you need it most.

- Check Oil Levels Daily - Daily inspection of oil levels, including reserve make-up tanks (if equipped), will prevent surprise shutdowns due to low oil pressure.

- Check Coolant Levels Daily - Change in reefer load quantities from low to high can affect engine operating temps causing some coolant to release from the system. Daily inspection can reduce shutdowns due to low coolant levels.

- Keep up with routine maintenance schedules - The best line of defense against power pack failure is to keep fresh eyes on your machines as frequently as possible. Here are our suggestions:

-

- Every 250 Hours

- Change Oil and Filters

- Change Fuel Filters

- Inspect Belts and Hoses for Wear (Replace as Needed)

- Inspect for Oil and Coolant Leaks

- Address any concerns ASAP or contact Power Pool Plus

- Every 500 Hours

- Same as above PLUS change Air Filters

- Inspect radiator for dust and debris build-up. Note: clogged radiators should only be cleaned by professionals with the right equipment and skill to prevent delicate radiator damage.

- Every 250 Hours

These steps are only a few first response actions to keep your power pack generator healthy and operational. If there are other concerns or questions related to power pack maintenance, please contact Power Pool Plus for more details.

Considering a used Power Pack? Here's how to reduce risk.

Used reefer gensets, known as power packs, can offer refrigerated container operators both large and small an inexpensive way to expand their operation and increase refrigerated container throughput. Lower initial investment costs of used power packs also reduces financial barriers, allowing start-up operations the flexibility to gain entry into the reefer market.

Yet, buying anything used is risky. Knowing what to look for is key.

Understand your needs first.

Since the supply of preowned power packs may be limited, there’s a tendency to purchase the first one that comes along, usually the one that first appears to be in good condition. But it’s very important that the power pack you choose fits your needs correctly. A generator that is too large – having a kW rating that’s higher than your expected load - can be almost as bad as having one that’s too small for your needs. Our article on wet-stacking highlights this.

If your operation will need to power 20, 30, or 40+ reefer containers, then be sure your power pack is sized to meet at least 70% of that number consistently. In this way, you will not risk unexpected generator shut-down due to overloading and your connected load will be sufficient enough to avoid problems associated with wet-stacking.

Be realistic

Good or bad, used power packs will have a history to them. It's fair to assume that before being replaced most power packs are typically used right up to the point of near failure; until the very last bit of productivity is squeezed from their essence.

What remains is a worn-out engine that’s unable to maintain horsepower, a generator with windings that are nearly torn from the stator and unable to produce electrical current safely, a rotten container that’s rusted through, broken and unusable receptacles, plus many other failings. With thousands of dollars in perishable cargo at stake, used machines are hardly something that can be purchased AS-IS and be expected to provide quality power generation. This is the risk.

Even if the used power pack that you are considering is not nearly as bad as the one pointed out in this example, it is safe to say that purchasing a used machine will offer limited life expectancy and require some sort of additional investment. Major failures can happen at any time creating huge and unexpected repair bills with potentially long power pack downtime – what’s that worth?

These costs are real and need to be figured into the overall operating expenses of purchasing and owning a used power pack with questionable history and limited records availability.

A better solution,

One that won’t leave you stranded like an old, worn-out power pack might.

Allow Power Pool Plus to provide the right used power pack for you. Our experienced team will identify the right generator package that’s properly sized to meet your requirements. Because finding one that’s sized correctly for your needs may not always be easy.

Through our comprehensive inspection process and in-depth operational evaluations, Power Pool Plus offers peace-of-mind on every used generator package purchased through us.

Here’s how we do it

Once a used generator passes our initial operational analysis, it goes through a process that we call re-qualification.

The engine and generator are the core components of any refrigerated container power pack. So our re-qualification process focuses on documented and historical failure facts based on each make and model genset. And with 30 years’ experience there is quite a bit of history to lean on.

Our intent is to extend the service life of a known low hour engine or generator set at a cost savings to our customers – often times as much as half the cost of purchasing new.

Understanding that the negative effects of fuels, oils, coolants, water, UV rays, age, and dry rot are the #1 enemies of power units, we go through an exhaustive process on any used machine that we evaluate. Key engine and generator parts are evaluated and replaced as necessary to ensure a product that is capable of handling the demands of typical power pack operations.

Other components like the shipping container enclosure, fuel tank, receptacle panels, and controls are reconditioned or replaced as needed.

The end result will allow your operation to be successful through owning a used reefer power pack with the assurances of professional inspection and re-qualification provided at a significantly reduced cost over a new machine.

While it’s difficult to eliminate all risk when purchasing used gear, our team reduces the chances of failure significantly and provides our customers with equipment that will offer productive output while maximizing your operation’s profitability for years to come. And isn’t that why you’re looking for a power pack in the first place?

Don’t take the risk on your own. Trust Power Pool Plus to deliver results and savings.

*Remember to properly maintain your equipment according to manufacturer’s recommendations to ensure long operational life with minimal downtime.

How to manage black exhaust smoke

Attention to load will improve power pack performance.

Power packs are the lifeblood of most reefer cargo operations. Keeping them in top shape through regular maintenance is a necessity.

Understanding load and how it affects power pack health is a critical part of this process.

Is your power pack underloaded?

It might seem obvious that overloading a power pack can have negative implications for a generator’s performance. Yet under-loading can be just as serious, if not more problematic to its long term health.

What does it mean to under-load a power pack?

An underloaded power pack is defined when the amount of load (Reefers) is far below the available power (Plugs) that the power pack is equipped to handle.

This situation may be unavoidable from time to time as there may only be limited numbers of refrigerated containers in your yard - as might be the case between shipments. Other times, it is a practice done intentionally under the misconception that this helps prevent the generator from having to work too hard.

The negative effects of under loading (wet-stacking).

Professionally built Power Packs are designed to precise specifications based upon the amount of load (or electricity) they are demanded to produce. Anything short of that, and the generator is not operating to its fullest potential. They will use more fuel, burn oil, and wet stack (produce black smoke) – issues that in time will lead to a shorter equipment life expectancy and sudden failure.

If you are experiencing black exhaust smoke issues, a rather common occurrence called wet-stacking is likely due to the power pack's lack of load.

Solution

To correct this situation, avoid running them on less than the optimal load for long periods of time. We understand that this may not always be practical given the number of reefers available. However, diesel-powered generators perform best when they are fully loaded up with reefer plugs. So be sure to manage them to full capacity periodically or consistently maintain them at an optimal load per generator.

What is the optimal load?

The number of actual reefers needed to obtain optimal load will vary from one size power pack to another. As a general rule of thumb, it is recommended to maintain a minimum of 70% capacity to reach the point at which the generator is working efficiently enough to burn cleanly and avoid maintenance concerns like wet-stacking (Black Exhaust Smoke).

As an example, the optimal load on a 40 plug power pack should be around 28 reefers. This is provided, of course, that the 40 plug power pack is built to proper specification.

* Care should be taken for hot boxes being brought down to temp not to overload the unit. Always follow the manufacturer's recommended operating instructions.

Conclusion

When possible, load up your Power Packs and let them run. Do this, and your black exhaust smoke issues will go away. But if problems persist, it could be signs of a bigger concern. Contact Power Pool Plus for further direction to help resolve.

Have other Power Pack performance questions? Contact us today.

Power Pool Plus welcomes LATAM sales manager

Power Pool Plus Welcomes Jose Alberto Castillo Magaña as Sales Manager of LATAM

Alberto provides his experiences in customer support to port equipment sales

(Alpha, New Jersey USA) Power Pool Plus is proud to announce the addition of Alberto Castillo as our Regional Sales Manager of Latin America. Alberto joins Power Pool Plus with past experience in addressing the heavy lifting requirements of both port and construction equipment operators. Mr. Castillo will be responsible for developing new business relationships and promoting our reefer generator products and related services throughout Mexico, Central America, and South America. Mr. Castillo is trained in mechanical engineering and is an accomplished sales professional with experience in solving unique challenges that maximize customer efficiencies.

Ports throughout Latin America are ever expanding their footprint in the perishable goods trade. This new role with Power Pool Plus will be to provide unique power generation solutions for port operators that are actively engaged in the throughput of refrigerated container cargo. Alberto is no stranger to the requirements of port operations. Based out of Mexico City, Mr. Castillo has most recently represented Taylor Machine Works International as the Regional Sales Manager of Mexico and SITSA in Mexico City as Sales Representative for Kalmar equipment and terminal tractors. Both roles addressed the capital equipment needs of port facilities.

According to Adam Hulse, VP Sales, “Having a regional representative in Latin America has been a goal for Power Pool Plus for some time. Alberto’s valued experiences and innate appreciation for meeting customer expectations is a perfect fit to the character of Power Pool Plus that we believe our customers in this region will benefit from. Everyone on our team is very excited to have him on board with us.”

“Power Pool Plus has the right products to address port operators throughout Latin America,” says Mr. Castillo. “I am excited about this opportunity to apply my knowledge and creative imagination in helping our customers with their reefer power needs.”

From spikes in seasonal cargo throughput to the efficient use of power packs to mitigate challenges in dependable ground power, Power Pool Plus is committed to helping port operators throughout Latin America to be successful in managing the ever expanding volumes of refrigerated container cargo. Mr. Castillo’s experiences and professional acumen will be an asset not only to Power Pool Plus, but to the customers that he will effectively serve.