Know when to replace your power cables

Check your power cables for safety and functionality

Without quality power cables to transfer electricity from the power pack generator to reefer racks or remote receptacle trees, keeping a reefer yard filled with refrigerated containers would be impossible.

Yet even the best-made cables require proper maintenance to ensure functionality and worker safety.

The ground cabling we use is dual-jacketed to protect the inner copper strands from damage. Yet, the constant dragging of cables across asphalt and gravel yards can take its toll.

Using color-contrasting layers provides a visual indicator. For example, when the outer jacket is worn through, cut, or scraped, the inner jacket reveals a distinctly white visual warning that it may be time to replace the cable.

This visual awareness provides easy identification of abrasion before reaching the copper stranding to ensure the safety of the operators.

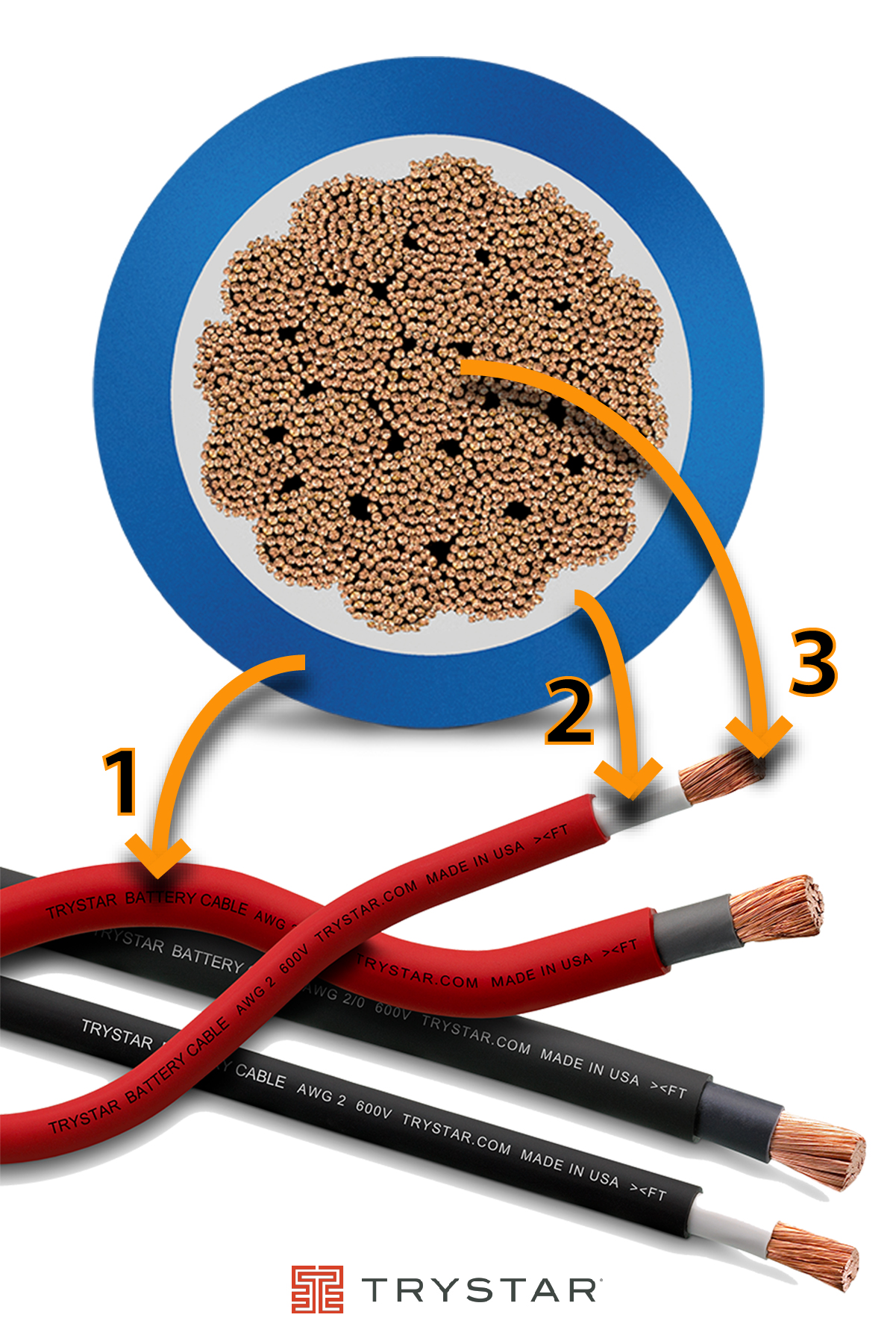

See the image below provided by our friends at Trystar cable, which highlights the dual-jacket layers.

- Outer Jacket

- Inner Jacket

- Copper strands

A best practice when handling ground cables is to pick them up and move them into position to avoid unnecessary scuffs. Protect them from moving vehicle traffic, do not allow them to lay in pooling water, and inspect them frequently for damage.

Get a quote today, on your next Purpose-Built Power Pack.

Ted Shelson

VP Marketing

Power Pool Plus

How we're meeting today's supply chain challenges

An unprecedented challenge.

COVID shutdowns and lost labor time, shipping delays, crippling storms, and raw material shortages - Nearly all suppliers and end-users are experiencing challenges due to the inability to secure the parts and materials needed for timely production.

Power Pool Plus is no exception.

Even with the increased manufacturing capacity from our newly opened Greenwood, South Carolina plant, which affords us an additional 30,000sqft on 12+ acres of manufacturing space, delays in receiving raw materials for production prove problematic and negate any impact from this infrastructure investment.

For example, steel and electrical cable, two of the most used materials in our Power Packs, usually promised from our vendors in a few days, is now turning into 6-8 weeks or more. Our challenges are their challenges, as they count on commitments from their suppliers to turn products. It’s a vicious cycle.

According to a recent Wall Street Journal Report, up to 40 vessels anchored off Southern California ports had been waiting for dock space, which has since ebbed to around 17 earlier this week. While that is still too large a number, the backlog continues to shrink as ports and trucking catch up with the increased volumes.

But still, we are finding various steel products disappearing off our vendors’ shelves. And the availability of 20 and 40-ft high cube containers is also difficult to find at once typical prices. We continue to order in higher quantities than usual to stay ahead, so we have inventory to keep up with the demand.

While inflation has primarily been kept in check, there is talk about possible increases later in the year.

The good news is (there's always some good news),

as the world awakens from its COVID-induced sleep, it is clear that the demand for goods is strong. Consumers are looking to buy, and industries are ready to make investments to meet the demand. Refrigerated transport is no exception. As the demand for fresh produce increases, the need for power at ports to manage reefer throughput will remain high.

Our power packs are needed, orders are up, and accordingly, we have made investments in our production facilities to stay ahead.

So be patient. These delays will pass, and a sense of normalcy will resume. Until then, please know that all of us at Power Pool Plus are working hard to provide you with the finest Purpose-Built Reefer Power Genset on the market while remaining at a reasonable price to help your operation succeed.

Suppose your reefer management team is looking to increase productivity this year with new Power Pool Plus power packs. In that case, we highly suggest placing orders as soon as possible to minimize potential delays and expected increases in material costs.

Get a quote today, on your next Purpose-Built Power Pack.

Ted Shelson

VP Marketing

Power Pool Plus

A Perfect Storm flooding reefer terminals (and it's not water)

With the ever-increasing demand for year-round fresh fruits and vegetables, refrigerated containers full of perishable produce are hitting US ports at staggering rates. The need for ports to accept these reefers is demanding. But will this flood of reefers swamp terminal operators?

Why are refrigerated containers stuck in port?

In some cases, container ships arrive into port with more reefer to off-load than initially forecast, putting an incredible strain on the port operator to round up enough reefer receptacles for a load of containers.

Under normal times this may not be a problem. But these are not normal times.

Increased refrigerated container traffic combined with multiple ships arriving back-to-back allows little time for some port operators to move reefer off the terminal before the next ship arrives. Compounding these challenges is the decreased availability of truckers due to COVID. Without truckers to haul this cargo, everything sits - preventing terminal operators from moving reefer out of the port quickly.

But unlike dry containers that can be stacked and positioned just about anywhere in the yard, refrigerated containers require a constant supply of electricity to keep the perishable goods within temperature specs. Every reefer unloaded onto the terminal needs to quickly find an available electrical connection. The financial risk of cargo spoilage is real and is a challenging responsibility for port operators.

Here's a solution.

Ideally, moving these perishable loads out of the port as quickly as possible is the best solution. But when that's not an option, diesel-powered generators, called Power Packs, offer port operators the flexibility to ramp up reefer capacity quickly to handle sudden increases in container throughput. Power Packs uniquely accommodate thirty to fifty or more reefer cord connections. And because they are diesel-powered, they can be positioned anywhere space is available.

- Through short term rentals, terminal operators can quickly add capacity during traditional spikes in reefer throughput.

- Longer rental terms can help operators mitigate the disruptions from lengthy port construction projects.

- Custom designed power packs configured to meet an operators' unique requirements can be purchased for a permanent reefer power solution.

To weather the flood of reefer hitting your dock, Power Pool Plus maintains a fleet of power packs and their highly versatile cousin, PortaPacksTM, to help manage and keep the refrigerated containers safe while under the terminal operator's care.

How many reefer plugs do you need?

Ted Shelson

VP Marketing

Power Pool Plus

4 Essential Troubleshooting Tips for Power Packs

Reefer operators have only one thing on their mind, make sure that the refrigerated cargo under their care is kept safely to spec.

Having a diesel genset go down is never an option. But understanding a few of the issues that may cause a diesel generator to fail, may help to save the refrigerated loads and avoid a service call in the middle of the night.

Thankfully, most power pack failures are quickly resolved, and with some basic knowledge, can be managed successfully without having to wait for service.

To help your team through some of the most common issues, here are a few troubleshooting tips.

Power Pack will not start

- Check that the battery disconnect switch is closed, and the batteries are charged.

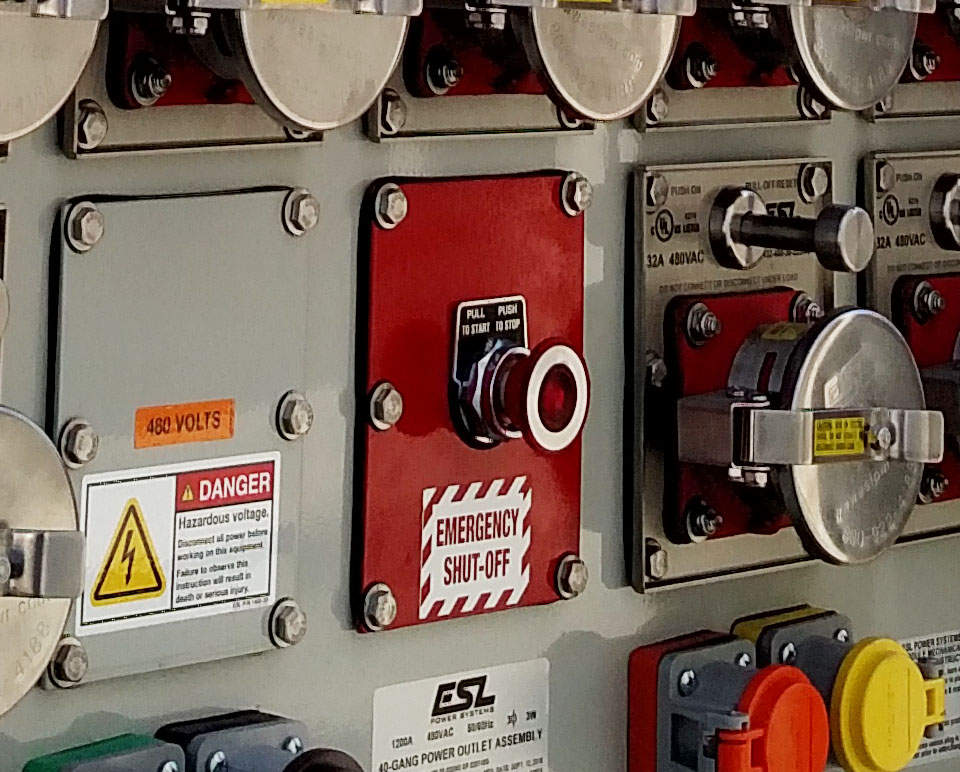

- Are the Emergency Stop Buttons

engaged (pushed in)? Pulling them out may start the generator. Ensure that no one is working on the generator or is inside the container enclosure before pulling out any emergency stop button. There are two E-Stop buttons - one located outside the main door and another inside near the control panel.

engaged (pushed in)? Pulling them out may start the generator. Ensure that no one is working on the generator or is inside the container enclosure before pulling out any emergency stop button. There are two E-Stop buttons - one located outside the main door and another inside near the control panel. - Is there fuel in the tank?

Yes, it may seem obvious, but our road service team has been called out many times only to discover a power pack that was allowed to run out of fuel. Note: after refueling, prime all fuel filters with fuel before restarting the engine. This will ensure a quick start and protect the fuel pump from damage.

Yes, it may seem obvious, but our road service team has been called out many times only to discover a power pack that was allowed to run out of fuel. Note: after refueling, prime all fuel filters with fuel before restarting the engine. This will ensure a quick start and protect the fuel pump from damage.

Power Pack shuts down without warning

- Fuel issues are the leading cause of power pack failures in ports. Poor fuel quality means clogged fuel filters. Change fuel

canisters and elements, and drain and clean fuel/water separators frequently. Prime all fuel filters.

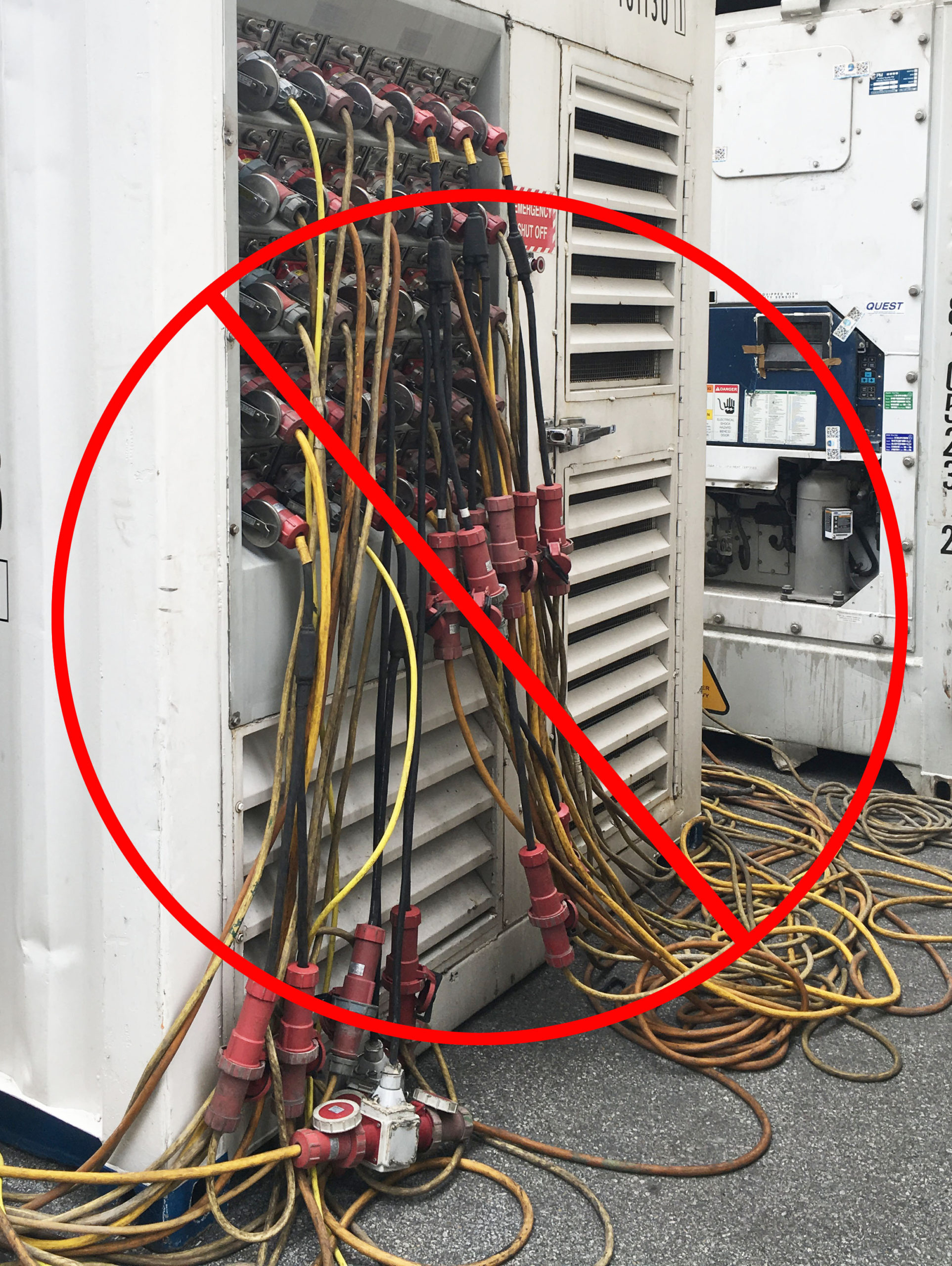

canisters and elements, and drain and clean fuel/water separators frequently. Prime all fuel filters. - Overloading power packs is a common problem, and can easily lead to generator shut down and loss of the connected load. It happens when the

reefer operator has more refrigerated containers to keep powered than available receptacles on the power pack. Beware of commonly used splitters to add capacity to power pack receptacle panels. An over-zealous operator may be inclined to connect as many as double the rated capacity of the power pack. It won’t take long to exceed the limitations of the power pack causing the main breaker to trip and cutting electrical current from the generator to the plugs.

reefer operator has more refrigerated containers to keep powered than available receptacles on the power pack. Beware of commonly used splitters to add capacity to power pack receptacle panels. An over-zealous operator may be inclined to connect as many as double the rated capacity of the power pack. It won’t take long to exceed the limitations of the power pack causing the main breaker to trip and cutting electrical current from the generator to the plugs. - Low oil level, low coolant level, and other alarm faults can cause your power pack to shut down to protect itself from damage. Before each startup, or at regular intervals during 24hr run cycles, visually inspect for leaks and worn parts, check and top off all fluids to proper levels, adjust loose belts or replace as necessary, and remove debris from the container compartment.

Power Pack runs but does not produce electrical power

- Check that the main breaker is engaged. Every power pack is different, but commonly located near the main control panel. Best practice is to engage the main breaker AFTER starting the engine.

Power Pack produces black exhaust smoke when running

- Black exhaust smoke is a common sign of wet-stacking caused by under-loading a generator. Power Packs come in many sizes,

typically identified by plug count (20-plug, 30-plug, 40-plug, and so on). They can carry a load equal to that number of refrigerated containers. Connecting less than half that amount over long periods is equivalent to starting your car and letting it run idle all day long, which is not ideal for the vehicle. A diesel engine will create soot, or unburnt fuel when operated like this. Too much of this carbon buildup will rob the diesel engine of vital power. Loading up the power pack to its capacity should clear most black smoke issues. If not, a load bank may be needed to replicate or add additional load to the power pack. Power Pool Plus can assist in this.

typically identified by plug count (20-plug, 30-plug, 40-plug, and so on). They can carry a load equal to that number of refrigerated containers. Connecting less than half that amount over long periods is equivalent to starting your car and letting it run idle all day long, which is not ideal for the vehicle. A diesel engine will create soot, or unburnt fuel when operated like this. Too much of this carbon buildup will rob the diesel engine of vital power. Loading up the power pack to its capacity should clear most black smoke issues. If not, a load bank may be needed to replicate or add additional load to the power pack. Power Pool Plus can assist in this.

Final Thought:

Power Packs are essential equipment for nearly every reefer operator. Setting aside even a small amount of time to understand a few of these concerns and how to address them quickly will go a long way in protecting your power pack and the valuable refrigerated load connected to it.

Questions? Contact Us.

The Power Pool Plus Service Team is available anytime to help keep your power pack reefer gensets running at their best, day or night.

Ted Shelson

VP Marketing

Power Pool Plus