Know when to replace your power cables

Check your power cables for safety and functionality

Without quality power cables to transfer electricity from the power pack generator to reefer racks or remote receptacle trees, keeping a reefer yard filled with refrigerated containers would be impossible.

Yet even the best-made cables require proper maintenance to ensure functionality and worker safety.

The ground cabling we use is dual-jacketed to protect the inner copper strands from damage. Yet, the constant dragging of cables across asphalt and gravel yards can take its toll.

Using color-contrasting layers provides a visual indicator. For example, when the outer jacket is worn through, cut, or scraped, the inner jacket reveals a distinctly white visual warning that it may be time to replace the cable.

This visual awareness provides easy identification of abrasion before reaching the copper stranding to ensure the safety of the operators.

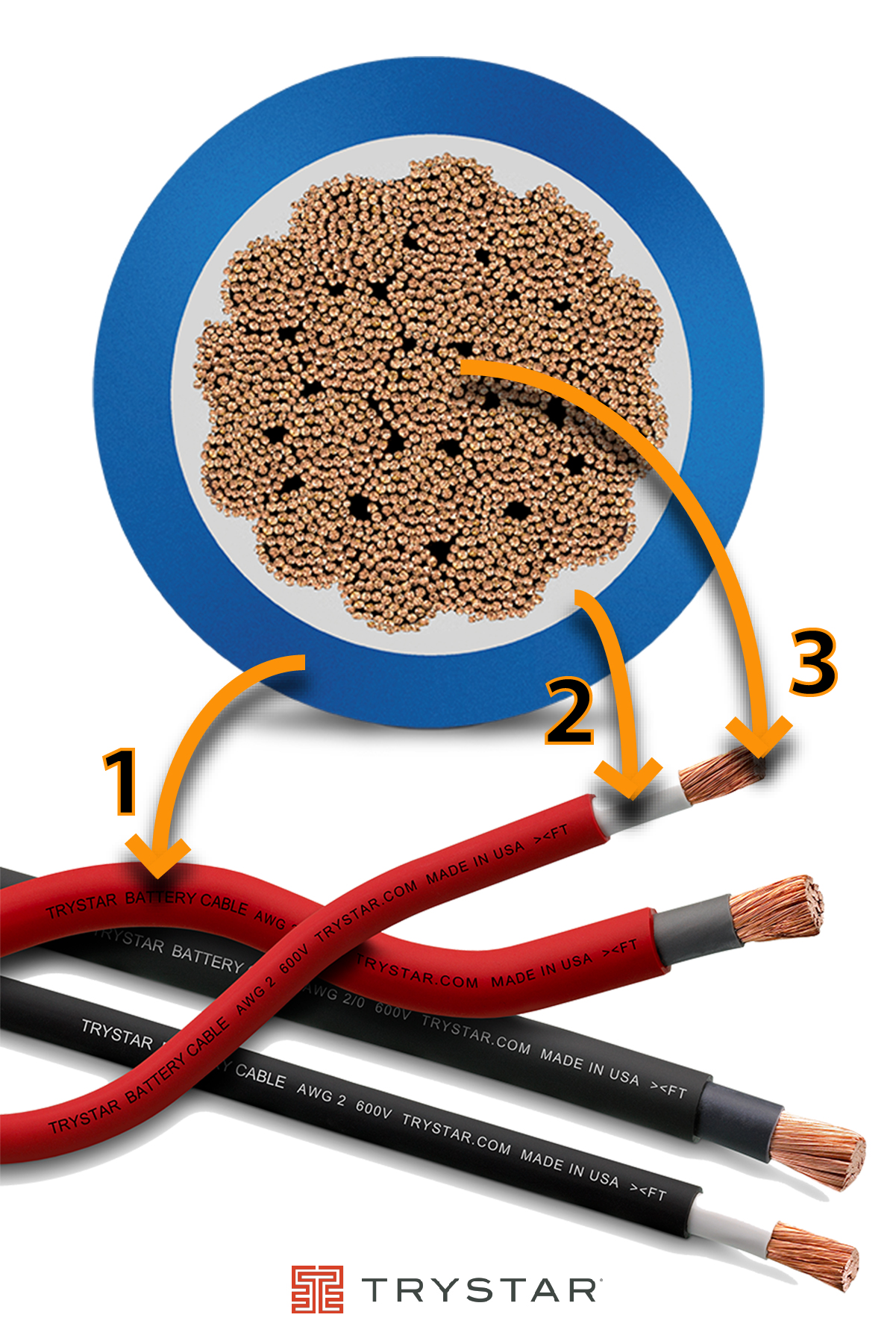

See the image below provided by our friends at Trystar cable, which highlights the dual-jacket layers.

- Outer Jacket

- Inner Jacket

- Copper strands

A best practice when handling ground cables is to pick them up and move them into position to avoid unnecessary scuffs. Protect them from moving vehicle traffic, do not allow them to lay in pooling water, and inspect them frequently for damage.

Get a quote today, on your next Purpose-Built Power Pack.

Ted Shelson

VP Marketing

Power Pool Plus